Think Safe. Think Competent. Think Experience. Think Ginlee.

BROKK DEMOLITION MACHINES

The Brokk demolition machine maximizes productivity on site, and is ideal for secondary demolition processES. The electric hydraulic drive means that there are no exhaust fumes, and lesser noise. Mobility is not a problem with its compact properties, making it ideal for difficult tasks in confined, inaccessible and high risk working areas. This system requires minimal manpower (an Operator and an assistant) to manage the remote controlled equipment. This makes for prompt work execution, with safety concerns easily monitored and addressed.

WALL SAW SYSTEM

The hydraulic power saw cutting system is designed for breaches and openings of escalators, travellators, lifts, windows, doors and other elements. Regardless of the type of job being undertaken, the powerful hydraulic wall saw system simply makes the technical demolition of heavily reinforced concrete and stone easier, safer, and more efficient. The wall saw system allows for horizontal and vertical cutting; even angular cutting; and is ideal where precision cutting is required.

CORING / STITCH CORING

Stitch coring/Coring is done together with Wall Saw system; to prevent over cutting, and where deep cutting is required. This method also works where there is limited working space for the Wall Saw, such as small tunnels, pit holes and basement slab. Single, common coring sizes range from 50mm to 400mm diameter.

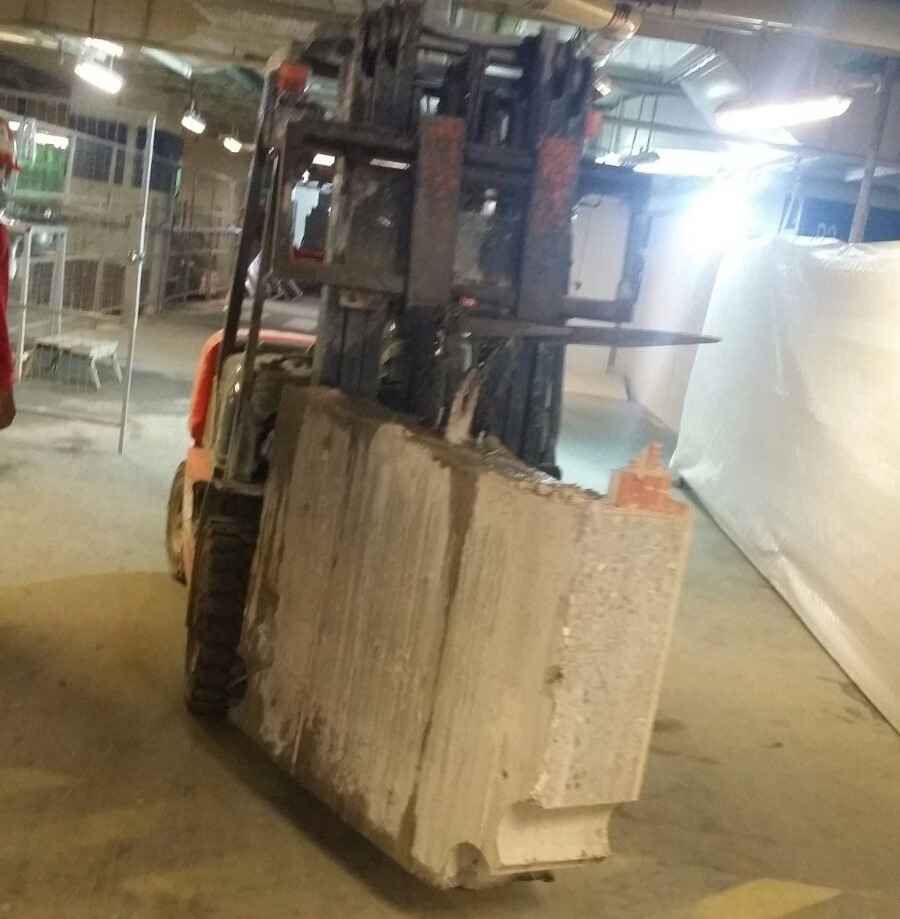

EXCAVATOR

Hydraulic excavators are versatile and especially useful in demolition processes; and are used under a range of operating functions such as crushing, loading, dumping, lifting, stripping, battering, among others. There exist a range of attachments for specified tasks as described such as jaw, grapple, impact hammer, pusher arm, bucket etc.

MEWP

Mobile elevated working platforms used for working at height operations include Scissor Lifts and Boom Lifts. Both serve multiple and different purposes for indoor and outdoor applications. Variable reach enables easy access and/or maneuvering over obstacles at higher levels; as necessary for execution of demolition works.

MIST MACHINE

Misting machines are the company’s solution to dust concerns during the demolition processes. They are especially useful with the following properties: Reduces probability of accidents with better visibility • Prolong usability/lifespan of equipment/its components; since continuous exposure to fine dust may cause friction on machine parts that may increase wear and tear. • Increase worker morale and productivity; because better working conditions are introduced with improved comfort level for workers.